In a recent trial, PEEK manufacturer Victrex™ claimed it saw a 9% increase in efficiency within automotive manufacturing conveying systems that utilized PEEK bearings. PEEK’s often pays for itself with these weight savings advantages leading to increased efficiency and longer part life. Even as a premium material, PEEK has a proven track record of reliably replacing specialty metals and materials that can cost up to ten times as much to service for same machinery or application and with a weight savings of up to 70% versus aluminum parts. We effectively utilize PEEK as a metal/stainless steel replacement in these harsh environments for weld washers, thrust washers, sleeve bushings and flange bushings, among others. In gas and steam industrial turbines, PEEK bushings reduce rotational friction and vibration, supporting loads able to turn at higher speeds without degradation and stand up to steam, hot water and the vast majority of corrosive chemicals. PEEK is, however, more brittle versus PTFE at these extremely low temperatures. PEEK excels in low-temperature environments as well, many times utilized in Arctic equipment for example both bearings and valve seals in Arctic wind turbines. PEEK exhibits superior mechanical and electrical properties with a maximum continuous working temperature of 480☏ to 500☏ and excellent retention of mechanical properties up to 570☏ in a steam or high-pressure water environment. Popular for high heat bushings and washers, PEEK plastic is a temperature-resistant semi-crystalline engineered machinable thermoplastic with excellent chemical resistance, fatigue resistance, and thermal stability. While UHMW, nylon, and acetal are the most utilized plastics for a wide variety of these applications, PEEK plastic offers additional benefits for specifically demanding applications, especially in corrosive and hot environments. PEEK, PI, PPS, PEI and other parts.PEEK plastic machining performed by Plastic Machining Company focuses on wear parts and power transmission components, generally in high heat applications. In addition, the company has horizontal injection molding machines, vertical injection molding machines, large-scale molding machines, high-precision CNC lathes, CNC machining centers, engraving machines, turning and milling and other machinery machining equipment, specializing in customized machining of various specifications and different purposes. After years of experience accumulation, Pinjin Company has been able to produce PEEK profiles of various conventional specifications and has a large inventory, and can customize and process unconventional PEEK profiles and PEEK profiles according to customer requirements.

With our expertise, we participate in the development of new products for customers throughout the process, provide technical support for customers from material selection, structure optimization, rapid prototype, product assembly and other links, reduce technical risks, control Research and development costs, improve product competitiveness.We has put into production a number of continuous extrusion production lines for PEEK bars, PEEK sheets, PEEK pipes,PEEK profiles, PPS rods, plates and tubes can be produced independently and in batches. Pinjin is especially good at machining PEEK special engineering plastics. You can directly send the drawings to and notify by phone or information.Ĭategories: Electronic Semiconductor, PEEK CNC Milling Parts Information includes: quantity, material, precision tolerance, surface treatment and special requirements.Our company can modify or design the drawings appropriately according to customer needs. Provide drawings (format: CAD, PDF, JPG, step, etc.) or samples.

On-site inspection and testing ensure the quality of materials and products.Right handling to minimize internal stress and avoid cracks in products.Tight tolerances, high precision, and custom specifications as request.Advanced machining technologies and equipment ensure accuracy and repeatability.Serves the analytical instrumentation, sample preparation, life sciences, marine, food processing and material handling industries. Prototype and low to high volume production offered with maximum 5,000 units.

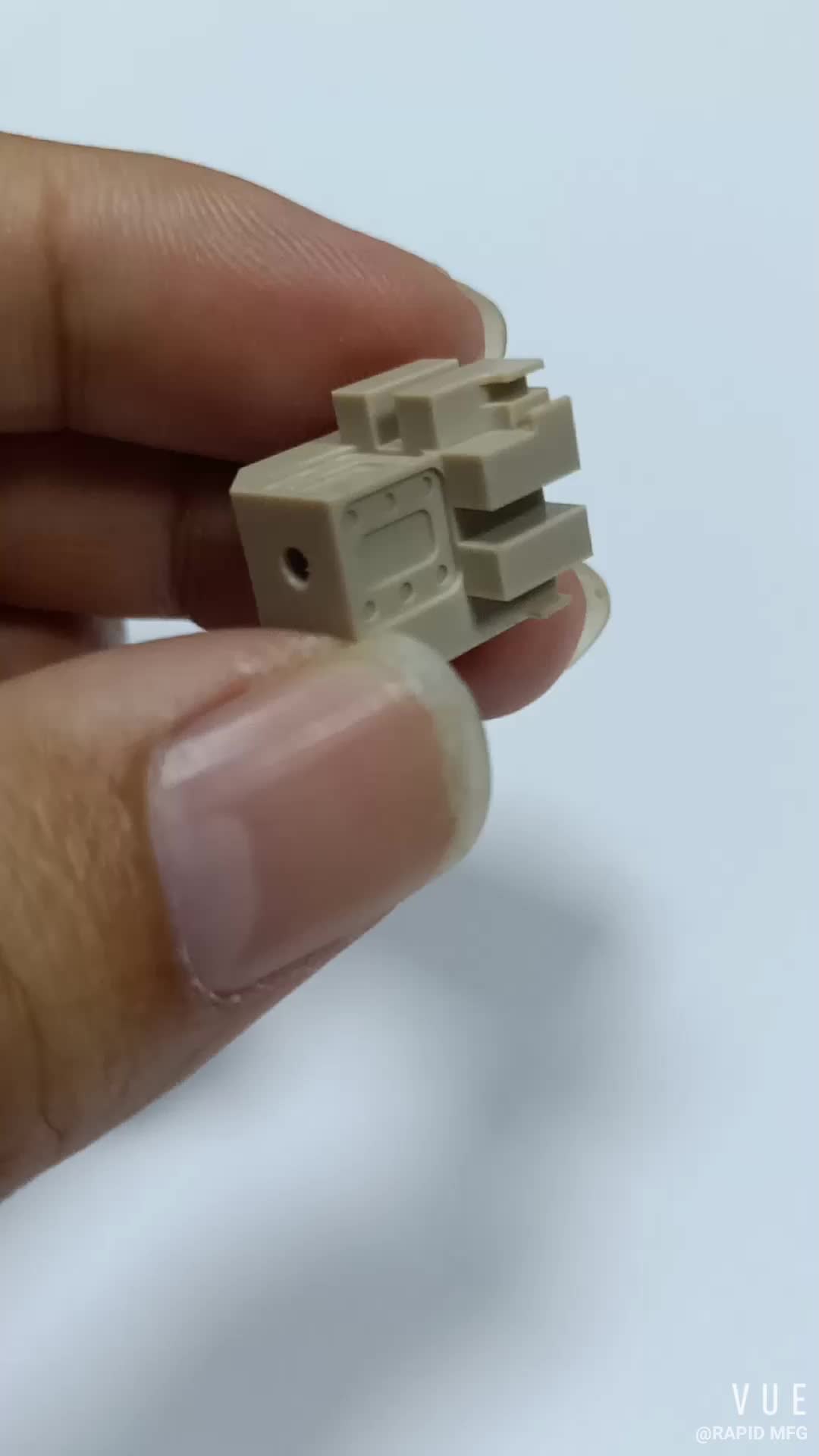

Capabilities include CNC milling, 3, 4 and 5-axis and vertical machining, turning, drilling and tapping. CNC machining services for Peek Engineering Plastic Special-Shaped Parts.

0 kommentar(er)

0 kommentar(er)